ISO 9001/AS9100 Certified

ATI’s State-Of-The-Art Fabrication Facility & Equipment

ATI's Aerospace Manufacturing Facility

Composite Blade & Scale Model Manufacturing

Advanced Technologies, Inc. (ATI) operates in a modern 84,000 square foot aerospace manufacturing facility that includes a precision machine shop, large model assembly areas, environmentally controlled composite areas, secured design and fabrication rooms and a controlled storage area. Our facility contains three (3) high bay fabrication areas totaling 24,500 square feet. The largest work area is 70’ x 150’. ATI also houses a 15,000 square foot precision machine shop with CNC and conventional milling machines and lathes.

ATI operates a Large-Scale Composite Tooling Facility within ATI’s main location. Our composite tooling facility houses an IRB 6400 ABB Dual Robotic Machine Center. The robotic machine has a milling envelope of 90 feet long, 16 feet wide, and 10 feet high. Though production of larger parts is possible, this would commonly be executed by the machining of multiple pieces that can be assembled into a single pattern exceeding 200 feet in length.

ATI has a custom Fatigue Testing Rig and two (2) environmentally controlled areas for composite fabrication totaling 13,500 square feet. The facility also features overhead cranes, heavy-duty forklifts, and an electric tug to handle tooling and components.

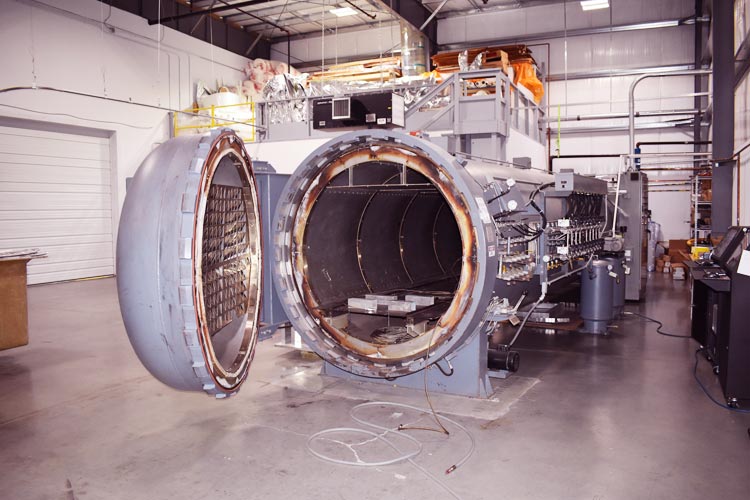

ATI has seven 3-axis CNC machines, two 5-axis CNC, 2 CNC lathes, two 3-axis wire EDM machines, 2 NC plycutting machines, 2 walk-in freezers for prepreg material storage, and 3 ovens for curing composites, and a 5' diameter autoclave. ATI has two large 3-axis CNC machines with travel limits of X=204.7” Y=102.4” Z=36.5” and X=157.5” Y=82.7” Z=30.0”. ATI has three large ovens, one electric infrared 4’ diameter by 33’ long, one autoclave 5’ diameter x 28’ long, and the other gas with an 7’-9” high x 10’-11” wide x 29’-6” long. All of ATI’s ovens have temperature chart recorders.

ATI’s Quality Assurance (QA) Department utilizes a state of the art 3-axis Brown and Sharpe 48” x 96” coordinate measuring machine (CMM) with direct computer control (DCC) operating on PC DMIS software. They also utilize one (1) FARO ION Laser tracker, one (1) FARO X Laser tracker, one (1) FARO Vantage Laser tracker, and one (1) FARO Platinum Arm operating with Verisurf software.

ATI’s Quality Management System is certified to ISO9001 and AS9100. ATI’s composite operations have been approved by Boeing Helicopter, Bell Helicopter, Sikorsky, Northrop Grumman, Carson Helicopter, and Erickson Air Crane to produce flight critical components.

All of ATI’s inspection tools are calibrated and traceable back to National Institute of Standard and Technology (NIST) standards.

EQUIPMENT

PRECISION MACHINING

CAPACITY

CAPABILITY

ACCURACY

Harrison V550 VS Gap Bed Bench Lathe

Harrison V460 VS Gap Bed Bench Lathe

TOSW100A Horizontal

Maho MH800P

P&W Jig Borer

Agie EDM

Accu AC-3KV Mill (2)

SEIKI-XL 3VX Mill (2)

Comet 3KYHD Mill (2)

Kingston Vertical Milling BM-5V

Monarch Precision Lathe

Sunnen MBC-1804 Hone

Kent KGS-618 Grinder

IRB 6400 ABB Robotic Machine Center

IRB 6400 ABB Robotic Machine Center

Vision Wide CNC Mill VF-5026

Awea CNC Gantry Mill

Wele CNC Gantry Mill

HAAS UMC 1000 CNC Mill

HAAS UMC 1250 CNC Mill

AWEA MEGA 5 CNC Mill

AWEA MEGA 5 P3032 CNC Mill

Haas VR-11B CNC Mill

HAAS VF5SS CNC Mill

HAAS VF5SS CNC Mill

Haas VF-5 CNC Mill

Mitsubishi MV1200 Wire EDM

Mitsubishi MV4800 Wire EDM

Kingston THA CNC Lathe

HAAS STL28T CNC lathe

21x80

18X60

63" x 49" x 44"

27" x 17" x 19"

12" x 18.5" x 25"

8" x 12" x 12"

36" x 16" x 20"

36" x 15" x 16"

36" x 14" x 16"

24" x 45" x 60"

12" x 24"

.125" dia - 6.5" dia

6" x 18"

90' x 16' x 10'

90' x 16' x 10'

204.7" x 102.4" x 36.5"

157" x 82" x 40"

84" x 63" x 31.5"

40" x 25" x 25"

50" x30" x 25"

118" x 57" x 30"

118" x 118" x 47"

120" x 40" x 30"

50" x 26" x 25"

50" x 26" x 25"

50" x 25" x 25"

12" x 16" x 8"

53.1" x 43.3" x 20"

34" x 120"

13" x 42.5"

Precision Turning

Precision Turning

Horizontal Boring Mill

Universal Milling

Precision Boring

Plunge Cutting

Milling/Drilling

Milling/Drilling

Milling/Drilling

Milling/Drilling

Precision Turning

ID Honing

Surface Grinding

6 axis N/C Milling

6 axis N/C Milling

3 Axis N/C Milling (DNC)

3 Axis N/C Milling (DNC)

3 Axis N/C Milling (DNC)

5-Axis CNC Vertical Mill

5-Axis CNC Vertical Mill

5 Axis N/C Milling

5 Axis N/C Milling

5 Axis N/C Milling (DNC)

3 Axis N/C Milling

3 Axis N/C Milling

3 Axis N/C Milling (DNC)

4-axis cutting

4-axis cutting

CNC Turning (DNC)

CNC Turning

0.0005

0.0005

0.001

.0001"

0.0001

.001"

.0005"

.0005"

.0005"

.0005"

.0002"

0.0001

.0001"

.090"

.090"

.0005”

.0005”

.0005”

.0005”

.0005”

.0005”

.0005”

.0003”

.0005”

.0005”

.0005”

.0001”

.0001”

.0001”

.0004"

EQUIPMENT

COMPOSITE FREEZERS/OVENS/PLY CUT

CAPACITY

CAPABILITY

ACCURACY

MER COMBI 3000 10' Automated Slab Saw

Taricco Autoclave

Eastman Plycutter Eagle S135

Eastman M9000

Gehnrich Curing Oven

Glenro Curing Oven

Composite Material Freezer

Composite Material Freezer

Composite Material Freezer

Despatch Oven

Despatch Oven

100 Ton Platen Press (Curing)

Enerpac 50 Ton Paten Press

Dake 25 Ton Platen Press (Curing)

10' x 2.5' cutting table

5ft dia x 28 ft long

6' x 24'

72" x 24'

8.5' x 30' x 6.5'

4' ID x 33'

8' x 30' x 8'

15' x 30' x 7'

12' x 10' x 20"

5' x 7' x 6' (550°F)

5' x 2-1/2' x 4' (575°F)

18" x 82" x 28"

N/A

22" x 11" x 10"

Composite Saw

Composite Curing Oven

CNC Fabric Cutting

CNC Fabric Cutting

Composite Curing

Composite Curing

Prepreg Storage

Prepreg Storage

Prepreg Storage

Athena Controller

Partlow Controller

Partlow Controller

N/A

Partlow Controller

.020”

(400°F)

.020”

.020”

(400°F)

(400°F)

(-10 to 0°F)

(-10 to 0°F)

(-10 to 0°F)

(550°F)

(575°F)

(400°F)

N/A

(400°F)

EQUIPMENT

INSPECTION

CAPACITY

CAPABILITY

ACCURACY

Brown & Sharp 7300 CMM

Faro XV2 Laser Tracker

Faro Laser Tracker ION™

Faro Advantage Laser Tracker

FARO Arm Quantum Max S

Faro EDGE 8 ft Arm w/ Laser Scanner

96" x 48" x 36"

35m (115’) Spherical working volume

110m (361’) Spherical working volume

160m (525’) Spherical working volume

8'6"

8'6"

Programmable inspection

Laser Tracker

Laser Tracker

Laser Tracker

Portable CMM

Portable CMM

.0001"

.002”

.002”

.002”

.0002”

.0002”